-

Wheel Bearing and Hub Assembly

- nn

- High-Grade Resin-Treated GCR15 Steel for Maximum Hardness and Extreme Temperature Resistance

- Specially Formulated Grease for Enhanced Thermal Dissipation, Superior Lubrication, and Water Wash-Out Resistance

- Triple and Quadruple Lip Sealing Technology and High Moisture Resistance Rubber for Maximum Bearing Protection

nn

nn

nn

$64.99 -

Wheel Bearing and Hub Assembly

GMB’s High-Grade Wheel Bearings and Hub Assemblies offer OEM strength and longevity. GMB Wheel Bearings & Hub Assemblies feature:

- High-grade GCR15 steel with G-10 resin finish prevents premature failure and is built for high temperatures and heavy loads.

- Premium grade ABS sensors with 99.9% pure copper wiring for greater electrical conductivity and optimal brake system performance.

- Triple and quadruple lip seal designs ensure your bearings have maximum protection from the elements and dust.

- Roll-formed hubs eliminate the need for welding, which improves strength (welding can create weak points within the hub, so we don’t weld our hubs).

With GMB’s 100% factory-tested Wheel Bearings & Hub Assemblies, you can be confident in weather protection, proper lubrication, and optimal hub performance.

$68.99 -

-

Universal Joint 210-1309

- nn

- Every GMB U-Joint features a Proprietary Protective coating for Maximum Durability.

- GMB Universal Joint Needle Bearings are Heat-Treated to withstand High Torque Loads

- GMB U-Joints are manufactured with Chrome-Molybdenum Steel, with Quality Control Processes that Meet or Exceed OEM Requirements

nn

nn

nn

nnIncludes all required hardware, including exact fit snap ring for easy installation.

$14.25Universal Joint 210-1309

$14.25 -

Universal Joint 210-0153

- nn

- Every GMB U-Joint features a Proprietary Protective coating for Maximum Durability.

- GMB Universal Joint Needle Bearings are Heat-Treated to withstand High Torque Loads

- GMB U-Joints are manufactured with Chrome-Molybdenum Steel, with Quality Control Processes that Meet or Exceed OEM Requirements

nn

nn

nn

nnIncludes all required hardware, including exact fit snap ring for easy installation.nnnn

$12.99Universal Joint 210-0153

$12.99 -

Fuel Pump and Strainer Set

nnnnOE Replacement Electric Fuel Pump Motors

nn

nn

nn

nnnnnnnnGMB Fuel Pumps use only durable, OE replacement electric motors. These motors are developed to match the manufacturer’s specifications in terms of voltage, amperage, resistance, pressure, and volume to guarantee long lasting performance, consistent fuel pressure, and steady fuel delivery. GMB Fuel Pumps also use 99.90% pure copper on the internal wiring for greater electrical conductivity and optimal performance.nnnnnnHigh-Grade Aluminum Cased Motors

nn

nn

nn

nnnnnnnnGMB Fuel Pump motors are encased in a plastic fixture, and then that fixture is enclosed in a high-grade protective aluminum heat dissipation sleeve made of 5052 grade aluminum alloy.nnnnnn150 Micron Pre-Pump Fuel Filters (Strainer)

nn

nn

nn

nnnnnnnnGMB Pre-Pump Fuel Filters (also called a strainer) have a 150 micron rating and are made from the best non-paper filtering material available. All GMB Fuel Pump Assemblies include a filter (strainer). Fuel Strainers are also included with fuel pump kits, where noted.nnnnnn

nn

nn

nn

nn

nn

nn

nn

$40.00Fuel Pump and Strainer Set

$40.00 -

Wheel Bearing and Hub Assembly

nnnnHigh Grade Steel Bearings

nn

nn

nn

nnnnnnnnGMB Bearings are made of a high strength GCR15 steel, subjected to a proprietary process to achieve maximum hardness, and then finally treated with a G-10 finish.nnnnnnRoll Formed High-Grade Steel Hub

nn

nn

nn

nnnnnnnnGMB Wheel Bearing & Hub Assemblies contain specially formulated bearing grease. This special bearing grease has superior lubrication, enhanced thermal dissipation, water wash-out resistance, and better ability to lock in oils to keep the bearings rolling at optimal performance!nnnnnn

nn

nn

nnnnnnnnnn

nnnnnnThis process ensures the structural integrity of the steel by eliminating the need for welding or creating weak points within the hub assembly for enhanced durability, performance, and reliability.nnnnnnSpecially Formulated Bearing Grease

nn

nn

nn

nnnnnnnnGMB Bearings are made of a high strength GCR15 steel, subjected to a proprietary process to achieve maximum hardness, and then finally treated with a G-10 finish.nnnnnn

nn

nn

nnnnnnnnnn

nnnnnnWithout grease, the best bearing in the world would fail very quickly. So, it’s important to use a high-quality grease that will last the life of the bearing.nnnnnnTriple & Quadruple Lip Sealing

nn

nn

nn

nnnnnnnnGMB Hub Bearing Assemblies use a triple and quadruple lip sealing technology. This technique uses high temperature resistant rubber to achieve maximum bearing protection against dust, water and road debris.nnnnnn

nn

nn

nn

nn

nn

nn

nn

nn

nn

nn

nn

nn

nn

nn

nn

nn

nn

$49.99 -

Engine Timing Belt Kit with Water Pump

nnnnGMB Timing Belt Kits with Water Pumpnn

nn

nn

nn

nnnnnnnnWith over 75 years in business, GMB is the premium bearing manufacturer to the OE and Aftermarket Automotive Industries. At the heart of every GMB Water Pump, Tensioner, and Idler lies a GMB Bearing. GMB performs quality assurance through rigorous industry-leading testing and control methods based on extensive research and proven proprietary processes. The parts GMB manufactures are all 100% factory tested to guarantee the perfect fit, form, and function.nnnnGMB kits include the Water Pump, Water Pump Gaskets, Timing Belt Tensioner & Idler Bearings, Timing Components, Timing Belts, Engine Seals, and Hardware necessary for installation on a specific vehicle.nnnnnnDirect OE Replacement Water Pump

nn

nn

nn

nnnnnnnnGMB Direct OE Replacement Water Pumps are precision-built and balanced to meet or exceed the original equipment specifications. GMB Direct OE Replacement Water Pumps are engineered and built utilizing the strictest design and manufacturing guidelines issued through ISO 9002 programs.nnnnnnDirect OE Replacement Tensioner, Idler, & Timing Components

nn

nn

nn

nnnnnnnnGMB OE Direct Replacement Tensioner, Idler, & Timing Components are precision-built to meet or exceed original equipment specifications and are quality assured through ISO 9002 programs.nnnnnnDirect OE Replacement Timing Belts & Seals

nn

nn

nn

nnnnnnnnGMB Direct OE Replacement Timing Belts & Engine Seals are sourced directly from the OE manufacturer.nnnnnn

nn

nn

nn

nn

nn

nn

nn

nn

nn

nn

$129.99 -

Water Pump

nnnnHigh-Strength Steel Bearing

nn

nn

nn

nnnnnnnnGMB has manufactured bearings for over 75 years in the global market for both the OEM and aftermarket industries. GMB has studied all aspects of bearing manufacturing to design the highest-quality bearings with proper high-grade steel, precision bearing race machining and polishing, and proper grease selection. GMB uses roller bearings for all high-load applications.nnnnnnProprietary Formulated Mechanical Seal

nn

nn

nn

nnnnnnnnGMB Mechanical Shaft Seals are made with proprietary elastomers and agents for protection and sealing power. GMB Shaft Seals utilize carbon and ceramic sealing surfaces for superior wear resistance.nnnnnnPrecision OEM-Spec Water Pump Housing

nn

nn

nn

nnnnnnnnGMB Water Pump Housings are manufactured to match the exact OEM-spec materials (cast iron, aluminum, or stamped steel). Each housing is precision measured using state-of-the-art technology to be dimensionally correct up to a 99% accuracy with strict tolerance limits.nnnnnn

nn

nn

nn

nn

nn

nn

nn

nn

-

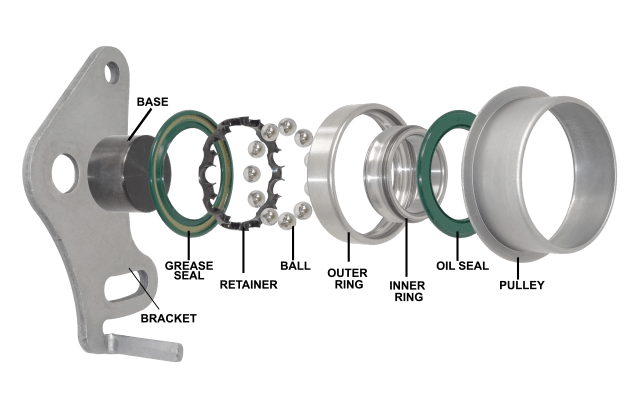

Wheel Bearing

nnnnHigh Grade Steel Bearings

nn

nn

nn

nnnnnnnnGMB Bearings are made of a high strength GCR15 steel, subjected to a proprietary process to achieve maximum hardness, and then finally treated with a G-10 finish.nnnnnnSpecially Formulated Bearing Grease

nn

nn

nn

nnnnnnnnGMB Bearings are made of a high strength GCR15 steel, subjected to a proprietary process to achieve maximum hardness, and then finally treated with a G-10 finish.nnnn

nnnnnnWithout grease, the best bearing in the world would fail very quickly. So, it’s important to use a high-quality grease that will last the life of the bearing.nnnnnn

nn

nn

nn

nn

nn

nn

$25.99Wheel Bearing

$25.99 -

Engine Timing Belt Tensioner

nnnnGMB has been an OE bearing manufacturer for over 70 years. With this experience, GMB has become one of the Top 5 manufacturers in the world.nnnnThe GMB Tensioner and Idler program offers extensive coverage for various Asian and European nameplates ensuring the right part every time.nnnnnn

nnnnGMB has been an OE bearing manufacturer for over 70 years. With this experience, GMB has become one of the Top 5 manufacturers in the world.nnnnThe GMB Tensioner and Idler program offers extensive coverage for various Asian and European nameplates ensuring the right part every time.nnnnnnWhy GMB TENSIONER & IDLER BEARINGS?

nn

nn

nn

nnnnnnnnNot all tensioner and idler bearings are the same. Here’s what makes ours stand out.nnnnnnKEY FEATURES

nn

nn

nn

nnnnnn- nn

- Rigorous testing and quality control for all bearing components

- Premium Triple-Lip Seal to maximize grease retention and prevent contamination

- High heat resistant grease

- Built to withstand high performance use

nn

nn

nn

nn

nn

nnnn

nnnnnn

nn

nn

nn

nn

nn

$19.99Engine Timing Belt Tensioner

$19.99 -

Wheel Hub Repair Kit

nnnn

nnnnnn

nnnnnnHigh Grade Steel Bearings

nn

nn

nn

nnnnnnnnGMB Bearings are made of a high strength GCR15 steel, subjected to a proprietary process to achieve maximum hardness, and then finally treated with a G-10 finish.nnnnnnRoll Formed High-Grade Steel Hub

nn

nn

nn

nnnnnnnnGMB Wheel Bearing & Hub Assemblies contain specially formulated bearing grease. This special bearing grease has superior lubrication, enhanced thermal dissipation, water wash-out resistance, and better ability to lock in oils to keep the bearings rolling at optimal performance!nnnnnnSpecially Formulated Bearing Grease

nn

nn

nn

nnnnnnnnGMB Bearings are made of a high strength GCR15 steel, subjected to a proprietary process to achieve maximum hardness, and then finally treated with a G-10 finish.nnnnnnTriple & Quadruple Lip Sealing

nn

nn

nn

nnnnnnnnGMB Hub Bearing Assemblies use a triple and quadruple lip sealing technology. This technique uses high temperature resistant rubber to achieve maximum bearing protection against dust, water and road debris.nnnn nnnnnn

nn

nn

nn

nn

nn

nn

nn

nn

nn

nn

$55.99Wheel Hub Repair Kit

$55.99

Shop By Department

- Arts,crafts & sewing

- Auto Body Parts

- Auto Parts

- Belt Drive

- Brake & Wheel Hub

- Cooling System

- Drivetrain

- Electrical

- Electrical-Bulb-Socket

- Electrical-Connector

- Electrical-Swich & Relay

- Engine

- Exhaust & Emission

- Filter & Air Hose

- Fuel System

- Ignition

- Oils & Fluids

- Steering

- Suspension

- Tires & Wheels

- Transmission-Automatic

- Transmission-Manual

- Wiper & Washer

- Babies & Moms

- Beauty & Personal Care

- Body & Soap Making Supplies

- Books & Office

- Hot Promotions

- Cars & Motocycles

- Clothing & Apparel

- Consumer Electrics

- Computers & Technologies

- Grocery

- Home Improments

- Home, Garden & Kitchen

- Health & Beauty

- Jewelry & Watches

- Pets Store

- Phones & Accessories

- Tools

- Sport & Outdoor

- Vouchers & Services