-

Fuel Pump Module Assembly

The Airtex Fuel Systems program features unique innovation and solutions by offering premium fit, form, and function as well as exceptional vehicle coverage and exclusive problem-solving features. Airtex Fuel Pump Modules, Hanger Assemblies, Tank Reservoirs, and Tank Sender Assemblies are built to meet or exceed OEM fit and reliability. Most applications include the necessary accessories such as tank seals, patented high-gradient density strainers and wiring harnesses. Fuel sensor design provides resistance to corrosive fuel blends and additives.

$94.99Fuel Pump Module Assembly

$94.99 -

-

-

Fuel Filter

Purolator Fuel Filters

PREMIUM FUEL PROTECTION

A clogged fuel filter could lead to contaminants in your fuel system – a common source of engine system failure. Protect fuel pumps and fuel injectors from these costly malfunctions by changing your fuel filter with a Purolator Fuel Filter replacement. Purolator® Fuel Filters scrub fuel clean of dirt, rust and other contaminants for smooth and efficient engine performance.

$9.99Fuel Filter

$9.99 -

Fuel Filter

Purolator Fuel Filters

PREMIUM FUEL PROTECTION

A clogged fuel filter could lead to contaminants in your fuel system – a common source of engine system failure. Protect fuel pumps and fuel injectors from these costly malfunctions by changing your fuel filter with a Purolator Fuel Filter replacement. Purolator® Fuel Filters scrub fuel clean of dirt, rust and other contaminants for smooth and efficient engine performance.

$9.99Fuel Filter

$9.99 -

Fuel Filter

Purolator Fuel Filters

PREMIUM FUEL PROTECTION

A clogged fuel filter could lead to contaminants in your fuel system – a common source of engine system failure. Protect fuel pumps and fuel injectors from these costly malfunctions by changing your fuel filter with a Purolator Fuel Filter replacement. Purolator® Fuel Filters scrub fuel clean of dirt, rust and other contaminants for smooth and efficient engine performance.

$15.99Fuel Filter

$15.99 -

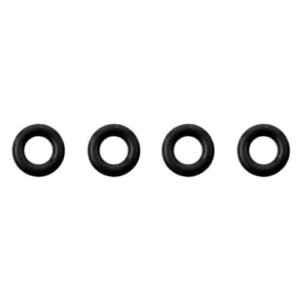

FUEL INJECTOR O-RING SET

Fel-Pro® gaskets offer 100% vehicle sealing with application-specific materials to give you sealing solutions with the performance and durability professionals trust.

Features & Benefits:Fuel Injector O-Rings

Fel-Pro fuel injector O-rings provide the proper

air-tight seal between the fuel injector and the

intake manifold, or the fuel injector and the fuel

rail. Virtually every vehicle on the road today is

equipped with these types of seals. Their

replacement may be required due to age-related

failure, or they may be replaced during fuel injector

service. Fel-Pro fuel injector O-rings provide the

proper sealing technology for these applications.$3.75FUEL INJECTOR O-RING SET

$3.75 -

Fuel Filter

PREMIUM FUEL PROTECTION

A clogged fuel filter could lead to contaminants in your fuel system – a common source of engine system failure. Protect fuel pumps and fuel injectors from these costly malfunctions by changing your fuel filter with a Purolator Fuel Filter replacement. Purolator® Fuel Filters scrub fuel clean of dirt, rust and other contaminants for smooth and efficient engine performance.

$18.99Fuel Filter

$18.99 -

Fuel Pump and Strainer Set

OE Replacement Electric Fuel Pump Motors

GMB Fuel Pumps use only durable, OE replacement electric motors. These motors are developed to match the manufacturer’s specifications in terms of voltage, amperage, resistance, pressure, and volume to guarantee long lasting performance, consistent fuel pressure, and steady fuel delivery. GMB Fuel Pumps also use 99.90% pure copper on the internal wiring for greater electrical conductivity and optimal performance.

High-Grade Aluminum Cased Motors

GMB Fuel Pump motors are encased in a plastic fixture, and then that fixture is enclosed in a high-grade protective aluminum heat dissipation sleeve made of 5052 grade aluminum alloy.

150 Micron Pre-Pump Fuel Filters (Strainer)

GMB Pre-Pump Fuel Filters (also called a strainer) have a 150 micron rating and are made from the best non-paper filtering material available. All GMB Fuel Pump Assemblies include a filter (strainer). Fuel Strainers are also included with fuel pump kits, where noted.

$40.00Fuel Pump and Strainer Set

$40.00

Shop By Department

- Hot Promotions

- Arts, crafts & sewing

- Auto Body Paint Supply

- Auto Body Parts

- Auto Parts

- Belt Drive

- Brake & Wheel Hub

- Cooling System

- Drivetrain

- Electrical

- Electrical-Bulb-Socket

- Electrical-Connector

- Electrical-Swich & Relay

- Engine

- Exhaust & Emission

- Filter & Air Hose

- Fuel System

- Ignition

- Interior Parts

- Oils & Fluids

- Steering

- Suspension

- Tires & Wheels

- Transmission-Automatic

- Transmission-Manual

- Wiper & Washer

- Beauty & Personal Care

- Cars & Motocycles

- Consumer Electrics

- Clothing & Apparel

- Grocery

- Home, Garden & Kitchen

- Health & Beauty

- Jewelry & Watches

- Computers & Technologies

- Babies & Moms

- Sport & Outdoor

- Pets Store

- Phones & Accessories

- Books & Office

- Home Improments

- Vouchers & Services